Skyhaven Systems’ Principals Wins Contract from NASA to Develop a Micro-Channel Reactor for Processing Carbon Dioxide to Ethylene

April 27, 2016 – NASA awarded a contract to Skyhaven Systems’ principals to develop and demonstrate a new micro-channel chemical reactor that can transform carbon dioxide to ethylene and other valuable chemicals for building a habitat on Mars. The processing of carbon dioxide is a continuing NASA need, ranging from separation processes to remove it from cabin air, to reaction processes that convert the Martian atmosphere to fuels. In support of future habitation activities on Mars, it is desired to process this high Martian concentration of carbon dioxide to ethylene, a chemical precursor that can be used to subsequently produce plastics including polyethylene, propylene, and polypropylene for building structures. Additionally, ethylene can be readily converted to ethanol and subsequently to sugar, important nutrients that support biohabitation. Toward this goal, Skyhaven Systems’ principals are developing an electrochemical micro-channel reactor that can convert carbon dioxide to ethylene. The modular architecture of the micro-channel reactor enables the system to be scaled to increase throughput while the small feature sizes of the reactor enhance thermal and mass transfer processes increasing the ethylene yield.

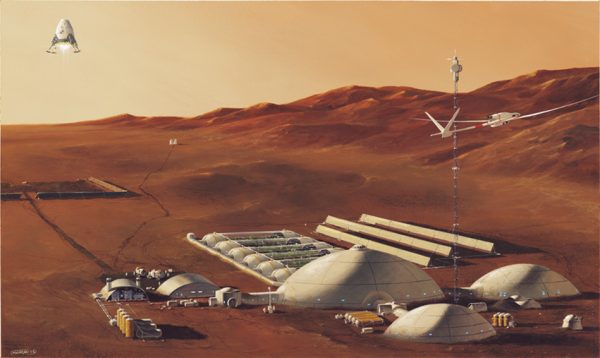

Mars is the ultimate destination of NASA’s human exploration program where the goal of using resources at the site of exploration will reduce launch mass and cost, and enable new missions not possible otherwise. Processing the carbon dioxide to ethylene in a compact modular micro-channel reactor will provide a valuable chemical that can further be used to produce habitat structures and equipment as well as ethanol and sugar nutrients for life support. For other commercialization pursuits, the conversion of carbon dioxide to ethylene can help reduce the concentration of this green house gas on earth while providing a valuable chemical feedstock. Over 109 million tonnes of ethylene is produced around the world, more than any other organic compound, where it is converted to a number of products. Newer production pathways to create this compound using micro-channel chemical reactors can help lower the capital and operating costs.